5 Ways to Save Money on PCB Manufacturing – 2024 Guide

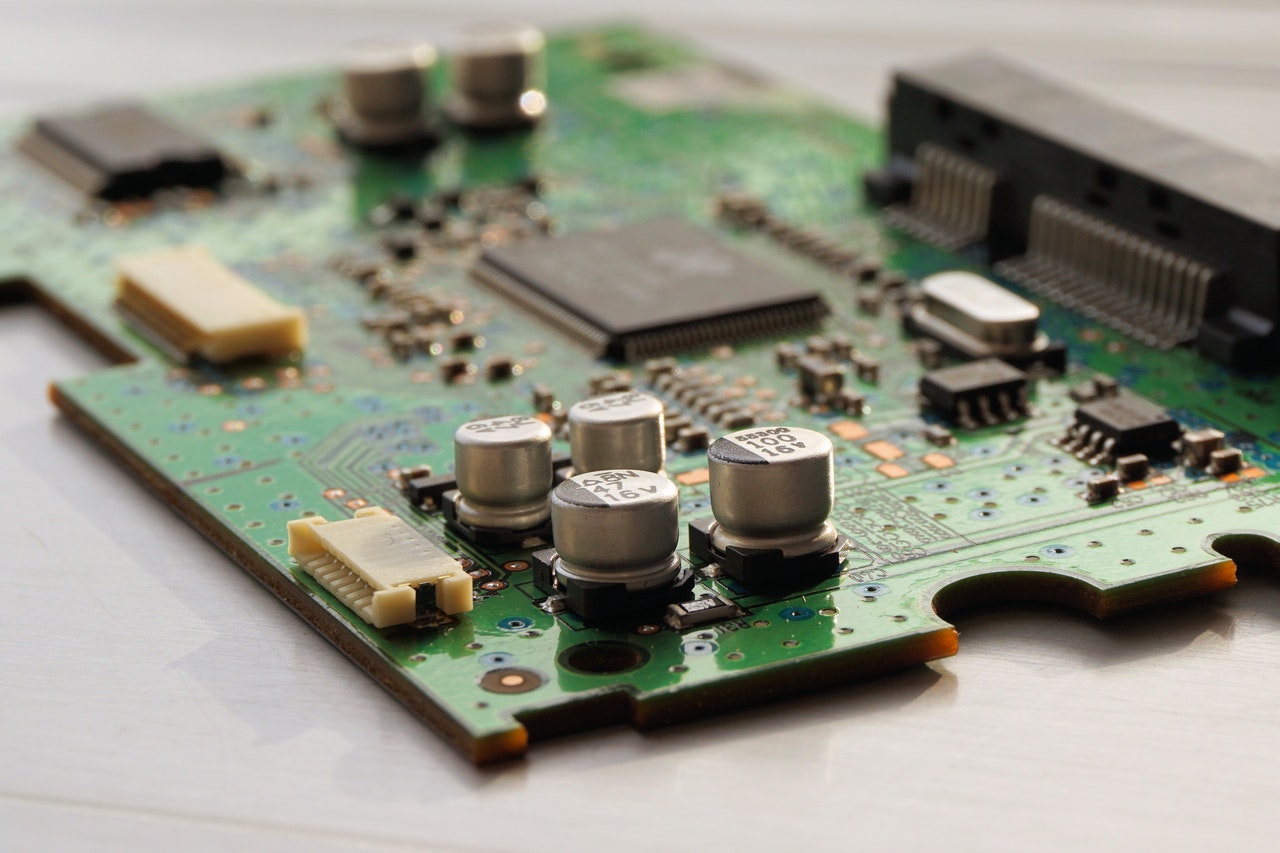

To get something like a PCB you have many things to. This involves machines as well as humans, but above all a large number of different processes that are necessary to complete the job. However, a big job does not always have to be the most expensive. Although you are concerned when it comes to PCB manufacturing, you don’t have to deal with it that much. We have a solution for your budget. There are a few simple ways to help you get through this production with your budget.

Just follow a few of our tips that will draw your attention to all the things you should avoid or the ones you should focus on. This way, you will surely be able to avoid frequent design mistakes that mostly cost your budget. So why spend more money if you don’t already have to? To avoid this, keep reading and discover ways to save money.

1. Less is more

What does this actually means? So, when we talk about the size of the board, it is important to mention the importance of that. It doesn’t have to be big. In fact, it is desirable to be small, so as not to spend a lot of money on this. This may be obvious to you, but most people think that this will produce a completely different effect. They are mainly guided by the fact that a small board requires great precision, and thus specific equipment and knowledge.

In the end, they think it all costs a lot more. That is not entirely true. If you strike the right balance and don’t make the board too small, you can’t spend a lot of money. It’s a matter of balance and between size and complexity. This is one of the most important factors that will cost you more or less. Of course, we must say that a larger board also has its advantages. It is easier to be made, but it also requires more money. In that case, you know what to do.

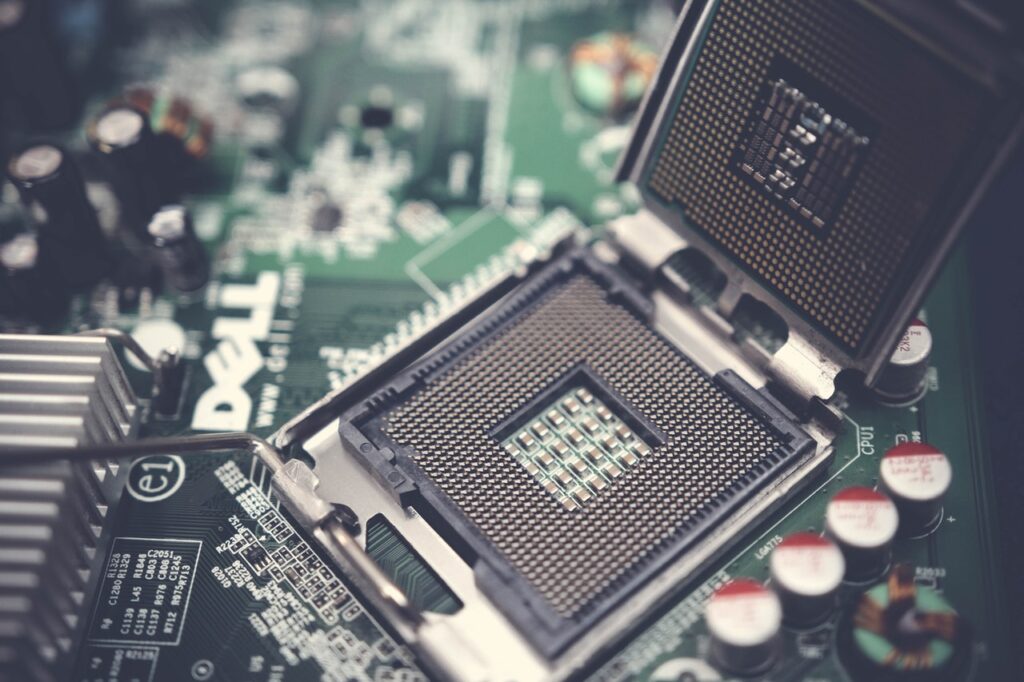

2. Choose quality

This may seem to you the opposite of what we are telling you, the truth is that saving money does not mean skipping quality. For example, you have decided on the cheapest variant when it comes to the layer stack. You probably thought then that you would save some money and that you could not go wrong. This is the first mistake that will cost you because you will need replacement. If you choose a board that is not of good quality, you risk breaking it.

That means you don’t know what you’re up to and you can expect to replace or repair it every day. It just goes that way with too cheap models. When you add up, that’s the only way to lose money in the long run. Instead, opt for some standard models that you know are of good quality. You can also make prototype to check everything. This page can give you more answers about PCB prototype as well as PCB assembly.

3. Stick to a neutral design

So we think it’s best for your budget to stick to a standard design. This means that you should avoid anything that is out of the norm. Of course, if you have totally different need you can do that. However, in any other case, this is an unnecessary waste of money because you will make the board much easier if you opt for conventional board shapes. This refers to the square or rectangular shape that is characteristic of it.

There’s really no need to bother with extra things like some weird shapes on the board. Anything contrary to the standard will require special needs that will cost you much more. Our advice is to do this part of the job as easily as you can, and it will also bring you some money to save.

4. Stick to the standard

It would be good to stick to some standards when it comes to size and components in the electronics industry. We tell you this for a reason. In addition to saving you money, it makes the whole process simpler and therefore more efficient. This way you fit into the budget while on the other hand you perform automated actions more easily. So, remember when we told you that less is more?

Stick to standard spacing and never reduce them. It can only bring you big expenses. The reason for this is the special work requirements due to the small distances between copper objects. Because of this, the machines will have to do much more precise work, because the package will automatically shrink. As we have already said, save your resources because in this case you lose a lot. Most things are related to machines, materials, processing, etc. It all costs a lot together.

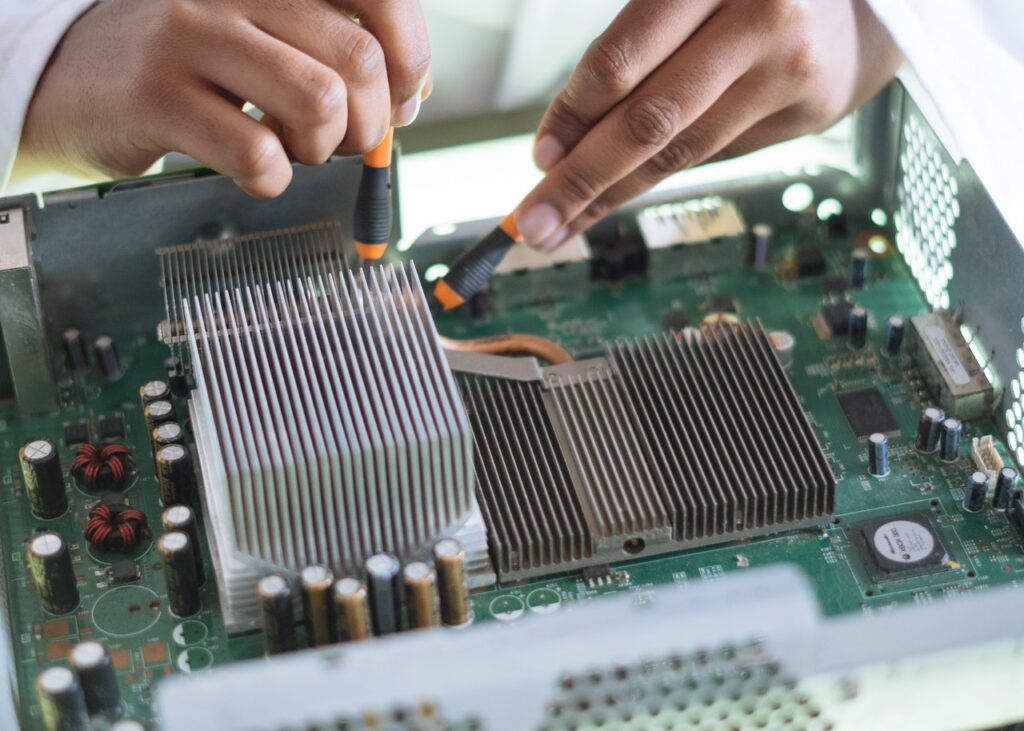

5. Avoid manufacturing errors

You can avoid all mistakes if you follow some general rules of business. This refers to the steps in the work process. Every step in production will depend on your needs. Due to its characteristics, a certain design sometimes requires some additional layers, more space, etc. Think about whether your design really needs all that before you decide to take a step in production.

For example, there is a big difference between a four-layer board and a two-layer board. You should adjust the number of layers to your work needs. If you do not need some processes during production, simply bypass them. There is no need to blindly follow these steps if your design does not need them. This way you will avoid unnecessary expenses.

Conclusion:

Whether you are a PCB hobby manufacturer or a rising manufacturer, it is important to think about your budget in addition to standard processes. We have shown you several ways that will make your entire business much more efficient, and in addition, you will save some money.

Keep in mind that the quality of the product does not have to suffer, it is enough to follow some of our instructions when it comes to design and other factors. Although saving may not be your primary goal, it is important to save your resources because you never know when you may run out of them.