The Future of Manufacturing: Exploring the Potential of CNC Machining

The manufacturing industry has come a long way in recent years, with advancements in technology revolutionizing the way products are made. One of the most exciting technological advancements in manufacturing is CNC (Computer Numerical Control) machining. It has rapidly become the go-to method for precision manufacturing, with its ability to produce complex designs with high accuracy and speed. In this article, we will explore its potential and how it is shaping the future of manufacturing.

Programs and Materials

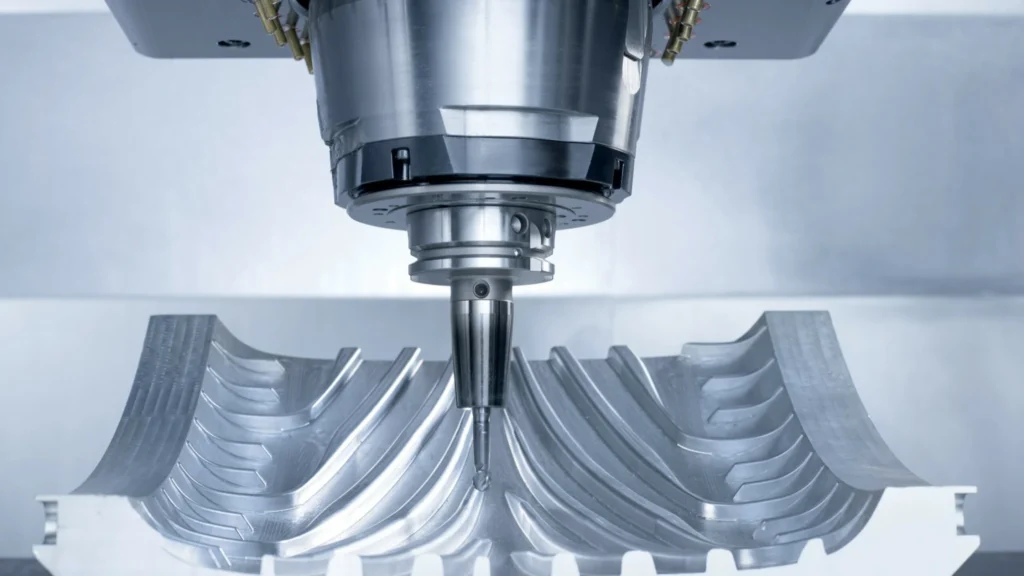

CNC machining is a process where a computer controls the movement of tools in order to shape a material into a specific design. This is achieved through a series of coded instructions that are programmed into the machine. The material can be anything from metal to plastic, and the design can be anything from a simple shape to a complex, intricate part. It has many benefits over traditional manufacturing methods, including greater accuracy, repeatability, and speed.

One of the major advantages of CNC machining is its ability to produce complex designs with high accuracy. This is because the machine is controlled by a computer, which ensures that each movement is precise and consistent. This means that even the most intricate designs can be manufactured with ease, and with very little room for error.

Advantages of CNC Machinery

Another advantage is its ability to produce parts with high repeatability. This means that each part will be identical to the last, ensuring that there is no variation in quality. This is particularly important in industries such as aerospace and medical, where precision is critical and any deviation from the design can be catastrophic.

It is also much faster than traditional manufacturing methods. This is because the machine can work continuously, 24 hours a day, 7 days a week, without the need for breaks or rest. This means that production times are greatly reduced, which in turn reduces costs and increases efficiency.

The potential of CNC machining is vast, and it is already being used in a wide range of industries, from automotive to aerospace, medical to electronics. In fact, it is becoming so popular that there are now many CNC machining services UK available, making it easier than ever for businesses to access this technology.

Industry

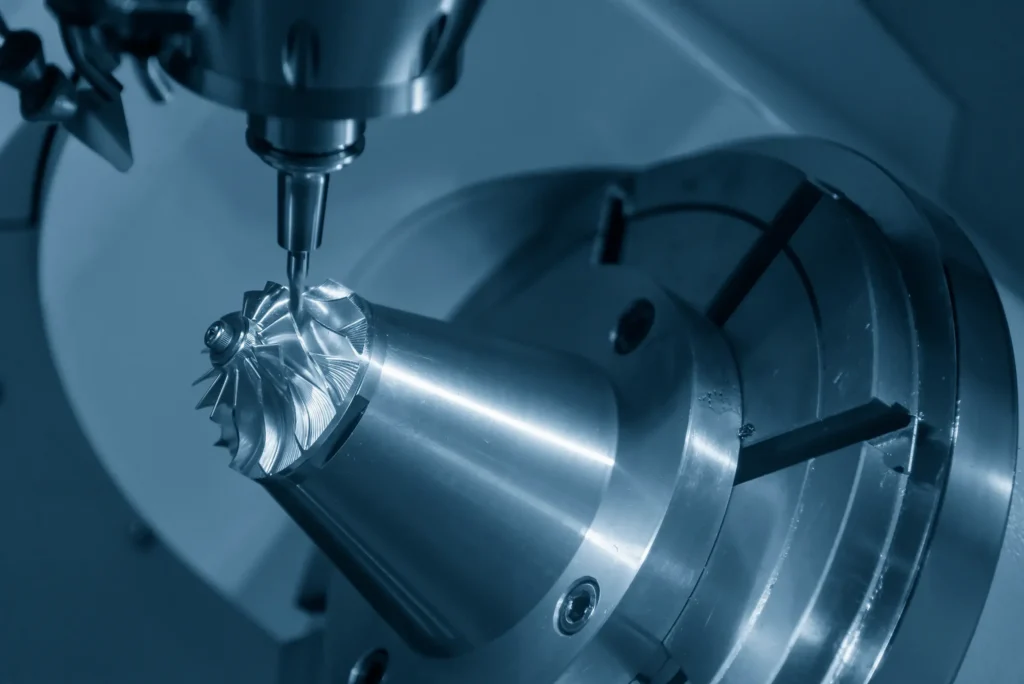

One industry that is particularly benefiting from CNC machining is the aerospace industry. CNC machining is being used to produce complex parts for aircraft, such as turbine blades and engine components. These parts require high precision and accuracy, and it is able to deliver this consistently, ensuring that the aircraft is safe and reliable.

The medical industry is also benefiting from CNC machining, with the technology being used to produce complex surgical instruments and implants. CNC machining is able to produce these parts with a high level of accuracy, ensuring that they fit perfectly and function as intended.

Producing Ability

It is also being used in the automotive industry, where it is used to produce parts such as engine blocks and transmission components. The ability to produce these parts quickly and accurately means that production times are greatly reduced, which in turn reduces costs and increases efficiency.

As CNC machining continues to evolve, we can expect to see even greater advancements in the future. For example, the development of 5-axis CNC machines will allow for even greater complexity and accuracy in the parts that can be produced. This will open up new possibilities in industries such as aerospace and medical, where precision is critical.

Conclusion

In conclusion, CNC machining is a technology that is revolutionizing the manufacturing industry. Its ability to produce complex designs with high accuracy and speed is making it the go-to method for precision manufacturing. As the technology continues to evolve, we can expect to see even greater advancements in the future, making CNC machining an essential part of the manufacturing industry.