Robotics In Manufacturing: What Are The Advantages And Disadvantages Of Soft Grippers?

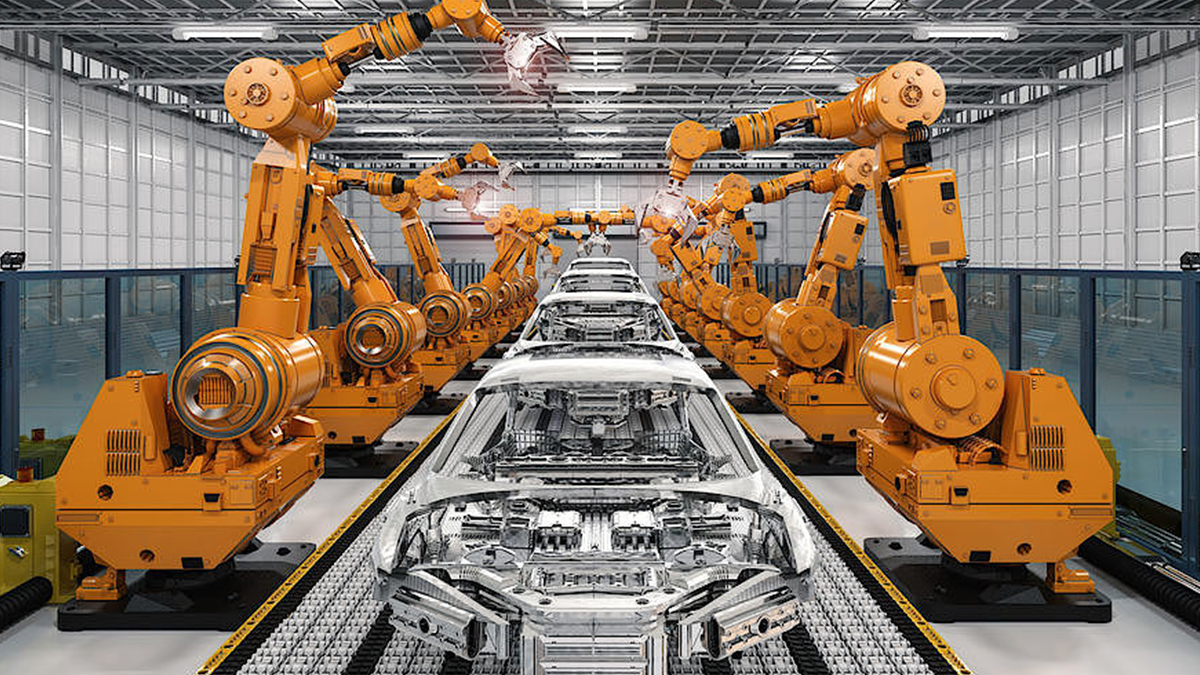

Robots have become increasingly prevalent in the manufacturing industry, offering numerous benefits, including increased efficiency, productivity, and quality. Here are some of the areas of manufacturing where robotics are commonly used.

The multiple applications of robotics in manufacturing

- Assembly: Robots can be used to assemble products more quickly and accurately than humans, particularly for tasks requiring high precision or consistency.

- Welding: Robots can perform welding tasks more efficiently and consistently than humans, and they can also work in hazardous environments without risking worker safety.

- Painting: Robots can be used for painting tasks, particularly in the automotive industry, where they can ensure a uniform finish and reduce the risk of overspray.

- Material handling: Robots can be used to move and transport materials within a manufacturing facility, reducing the need for manual labor and increasing efficiency.

- Inspection and quality control: Robots can be equipped with sensors and cameras to inspect products for defects and ensure consistent quality.

- Packaging: Robots can be used for packaging tasks, including picking and placing products, filling containers, and sealing packages.

- Testing: Robots can perform testing tasks, including stress testing and quality control testing, with high accuracy and consistency.

Overall, robots have become a critical component of many manufacturing processes, and their use is likely to grow as technology advances and becomes more affordable.

The application of robotic grippers in production lines

Robotic grippers are end-effectors or tools used in robotic systems to grasp, hold, and release objects in a manufacturing line. The primary function of robotic grippers is to pick up parts or products from one location and move them to another location.

Here are some of the specific tasks that robotic grippers perform in manufacturing lines:

- Part handling: Robotic grippers can pick up and move parts from one location to another within a manufacturing line, from a conveyor belt to a workstation, or from a storage bin to a production line.

- Assembly: Robotic grippers can be used to grasp and hold parts in place during assembly operations, such as welding, fastening, or gluing.

- Packaging: Robotic grippers can pick up and place products into packaging, including bags, boxes, or containers.

- Inspection: Robotic grippers can hold parts in place for inspection or testing purposes, including dimensional or quality control inspections.

- Sorting: Robotic grippers can be used to sort products or parts based on their size, shape, or other characteristics, such as color or weight.

Overall, robotic grippers play a crucial role in manufacturing lines by enabling robots to interact with objects and move them from one location to another with high accuracy and consistency.

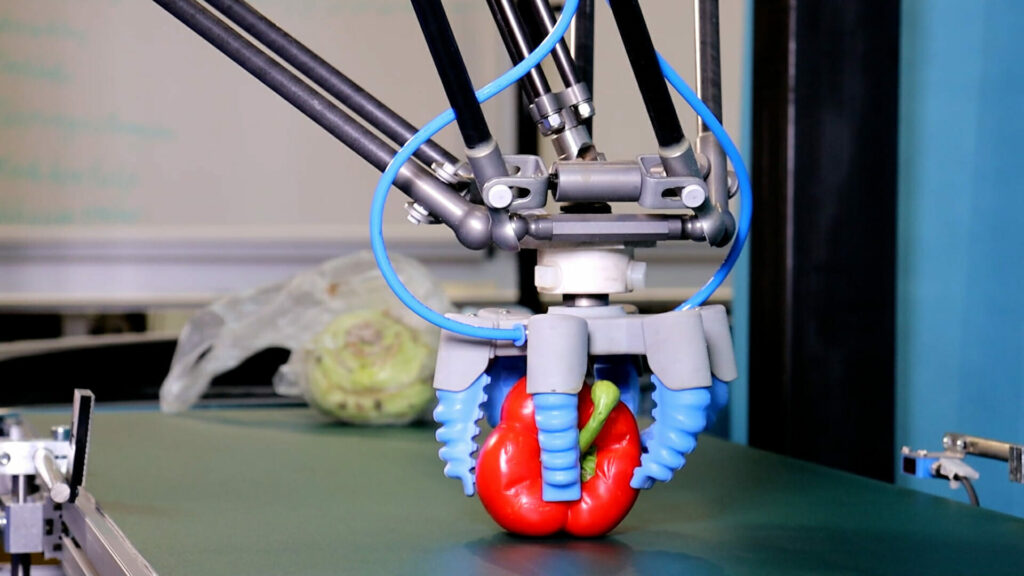

What are soft grippers?

A soft gripper is an end-effector or tool used in cobots and robotic systems with flexible materials such as silicone, rubber, or elastomers. These grippers have several advantages and disadvantages, which we will discuss below:

Advantages of soft grippers:

- Versatility: Soft grippers can conform to various shapes and sizes, making them well-suited for grasping objects with irregular or fragile shapes.

- Gentle grip: The soft, flexible material of the gripper allows for a gentle grip, which is ideal for handling delicate objects that a traditional gripper might damage.

- Lightweight: Soft grippers are often much lighter than traditional grippers, which can be advantageous in applications where weight is a concern.

- Cost-effective: Soft grippers can be relatively inexpensive and are often more cost-effective than traditional grippers.

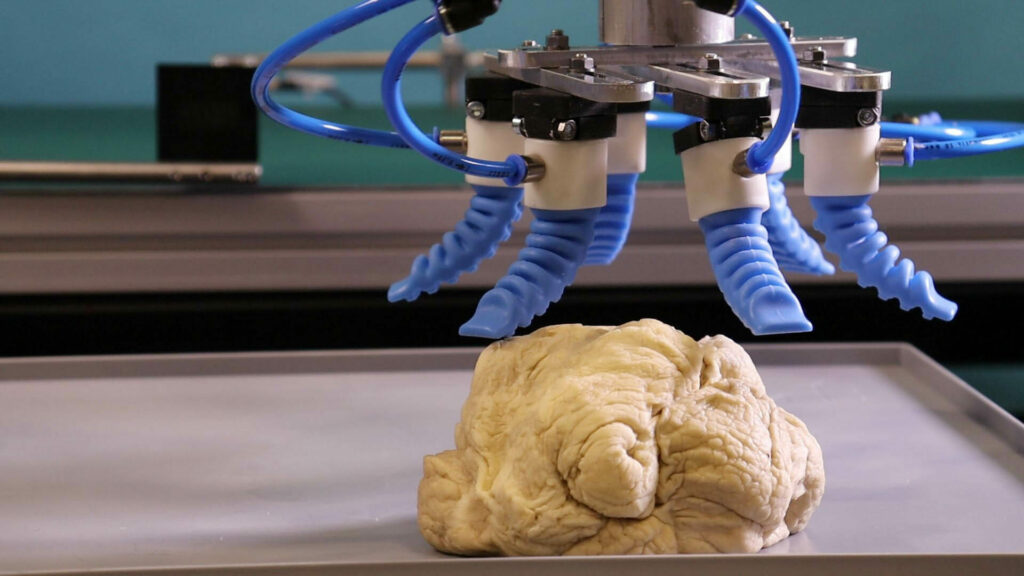

Disadvantages of soft grippers:

- Limited strength: Traditional grippers may be more robust than soft grippers, which can limit their ability to handle heavier objects or apply significant force.

- Wear and tear: The flexible material of soft grippers can wear out more quickly than traditional grippers, which can reduce their lifespan and require more frequent replacement.

- Limited temperature range: Soft grippers may not be suitable for extreme temperatures, as the flexible material may become too hard or too soft to function correctly.

Soft grippers can be helpful in many robotic applications, mainly where gentle handling and versatility are essential. However, they may only be suitable for some applications and may require more frequent maintenance and replacement than traditional grippers.