3 Different Types of Capsule Filling Machine and How They Work

The use of drugs and supplements as a dietary supplement can be seen to be dramatically increased. Nowadays for any disease, pain, or lack of vitamins, we can go to the nearest pharmacy and get our medicine in the form of a capsule or pill. Due to the increasing demand and consumption by people, the companies in the pharmacy could not manage to manually fill the products that are sold. So the filling machines appeared on the big stage. This invention has helped large pharmaceutical companies to meet market demands, and meet their needs in a timely manner.

Surely you have capsules in your home that you use every day, whether it is a cure for some kind of pain or as supplements, vitamins, and minerals as a dietary supplements. In one of the moments when you consumed the capsule, you must have wondered how the pharmaceutical companies manage to get that product, what the process of its composition looks like, and similar questions that went through your head at that moment. Today we will try to solve some of these mysteries and explain to you how the machines work. So stay tuned until the end to find out the answers to these questions.

How does this machine work?

We must first share with you one very important piece of information, and that is that these appliances are divided into 2 categories. The first category of machines is intended for personal use, where the configuration of the device is designed to fill a small number of pods that are for personal use. On the other hand, in the other category are the ones that are used by the big companies for mass production.

The machine for personal use, which has the capacity to fill a smaller number of capsules, works on a fairly easy principle. There is one part where you locate the empty shell, and in the other part, you put the powdery substance, the ingredients with which the pod will be filled.

How many types are there?

In the pharmacy manufacturing we can see three types of devices for making these pods, and today we will analyze all three types separately.

- Manual

- Semi-automatic

- Automatic

These are the three basic types that we can meet in this industry, and now we will move on to their characteristics and how they work.

1. Manual

The first thing you need to know about this device used in pharmacy is its capacity. This machine has a capacity of one session to fill a maximum of about 700 to 800 empty shells, which is quite a large number, but not enough to be used in mass production. The characteristic of this device is that we can mostly notice how it is used in cases when a smaller number of capsules need to be filled. This type of tool can be freely included in the category for personal or individual charging. What does hand polishing look like? The appliance has a tray with holes where one half of the capsule to be filled is placed. There is another tray where the substance is located, ie the ingredients with which the one half is loaded. The tool works like a kind of press, at the bottom is the tray with the empty half of the case, in the middle is the tray with the ingredients and at the top is the part with the handle on which is the other half of the empty capsule, which pulls down and closes the case.

2. Semi-Automatic

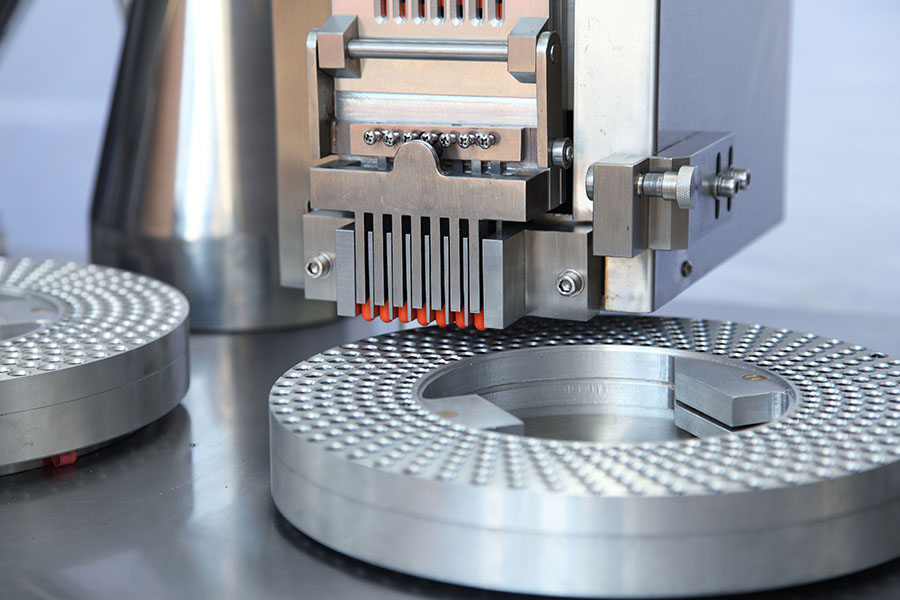

This is a device that is mostly used in factories where foil cases are mass-produced. Its main feature is that it can fill over 20,000 pieces on a single charge, depending on the model. From the very name of the machine, we can conclude that in the charging process are included mechanic filling, as well as the human hand, has a large share. One of the positive features that we can single out for this type of device is that it satisfies the hygienic needs because it offers filling of capsules in a clean environment. This is one of the biggest requirements that must be met by the pharmaceutical industry, and this machine can meet the same requirements. We can also mention that this type of device has a fairly long life, thanks to the material from which it is made, which is stainless steel. It is easy to maintain and operate, the capsules are placed in the part intended for them, a handle is drawn which distributes them in the gaps, in the part for the additive it is filled with it and a button is pressed on the machine that is intended to fill the foil pods. Next, the two parts are joined with the full and empty parts of the capsule and sealed, and the already sealed ones will come out in a separate compartment.

3. Automatic

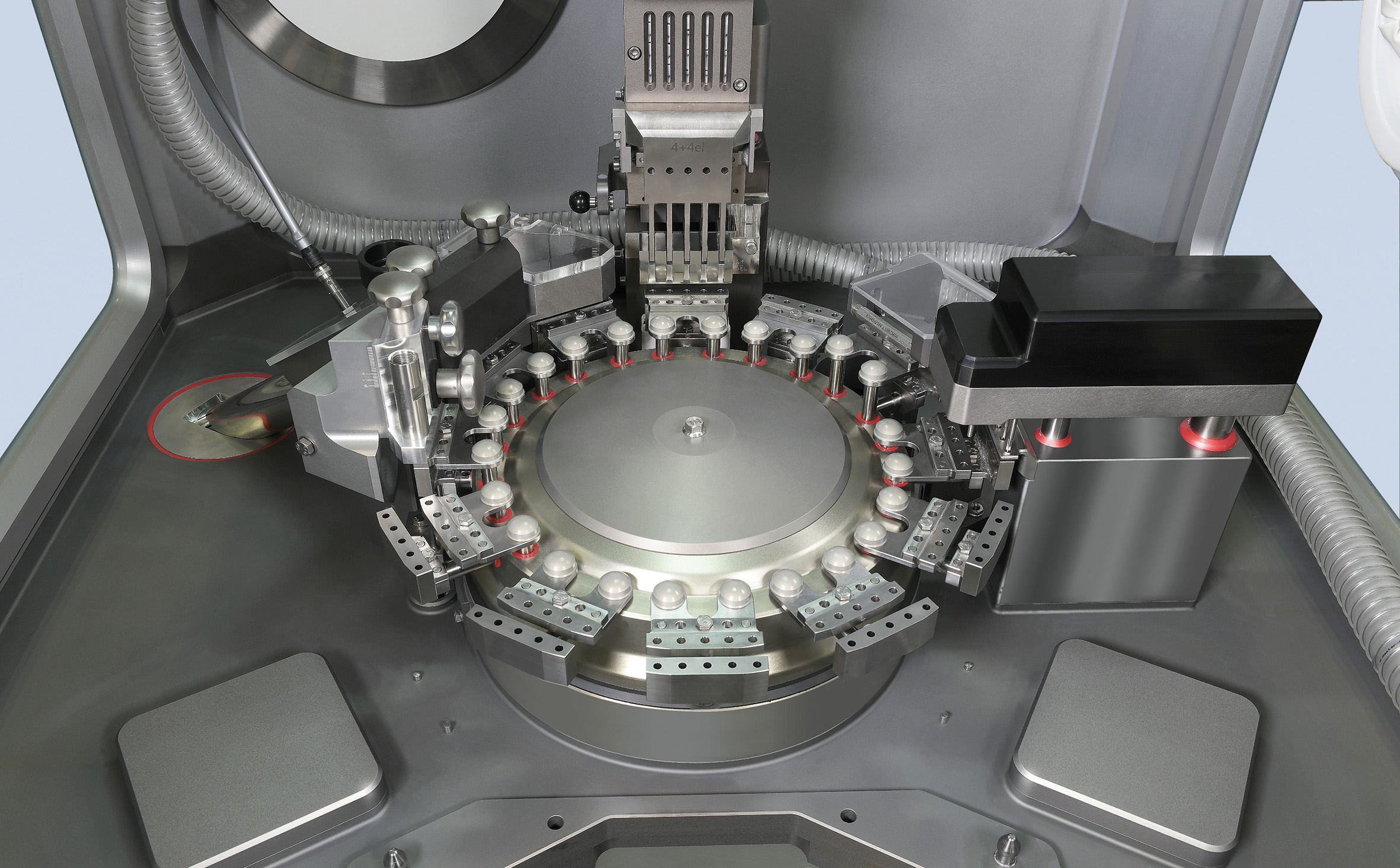

The capacity of this machinery is amazing, as it can fill up to 100,000 empty pods. This system practically works on its own, following the commands that you press on the buttons. This model works in a way that facilitates the complete production. The main goal of those who operate the instrument is to load it with a certain dose of filling grains and a sufficient number of foil cases. The appliance is filled in the special parts intended for the content and the capsules, the start button is pressed and the machine further does all the work. In the area where it is intended for the halves of the pods, the gaps are filled with the empty part of the capsule, then follows the filling stage and the final closing process. The interesting thing about this model is that, once the pods are filled, those that are damaged in the process are separated from those that are good for use. After the charging process is completed, the whole tool is cleaned with the special program it has.

Although all three types of devices have their good and bad features and are made of good materials, this does not mean that they need to be serviced regularly and some parts replaced. Some parts need to be replaced and serviced regularly such as the filling plate, the tray where the dusty substance is applied, and other small parts, for maintenance and servicing, as well as the replacement of parts you can find out if you visit this site.

Thanks to the advanced technology today we have a huge privilege, to quickly and easily get to the need capsules we need for everyday use. Many thanks to the instrument that fill the empty shells with the necessary ingredients quickly, easily, and with as few mistakes as possible. And of course, we have to thank those who handle them, without whose help we will not get the final product.