4 Common Heat Transfer Vinyl Issues and How to Fix Them

I have noticed in these past few years how most of my friends and acquaintances have their own cool, unique and interesting t-shirts. Whenever I ask them where they got them from, they just answer with DIY. For the longest time, I had no idea what that meant. I just smiled and nodded. But, once I discovered the world of DIY, a lot of things became much clearer. DIY or Do-It-Yourself is a method of creating or solving things by yourself. Although, creating DIY shirts is not easy unless you have heat transfer vinyl or HTV (HTV can be used for many other surfaces, not just shirts).

However, even if you do have these HTVs to put stickers and all kinds of images on your item, you still need to know how to properly use them. Otherwise, you will end up with a design that will look ruined from the start.

Do not worry, the whole process is not complicated at all. Anyone can do it. But, there are some issues that are very common which is why I am writing this article. I want you to be aware of those issues so that you can avoid them or at least, fix them.

Vinyl is not sticking

This is probably the most common and most frustrating part of the process. You follow every single step carefully and you still end up with a sticker that simply does not want to stick.

Well, if you are having this kind of issue, here are a few solutions.

Give it some time to cool

According to Zigpac.com, many people make the same mistake of removing the heat transferring vinyl immediately after they reach the required temperature. It is good that you are following instructions, but you still have to very careful. You probably need to let the newly added layer (sticker) to the surface to cool off before you try to peel it off.

There is no need to wait a lot. Just a few dozen seconds is enough for it to cool off. After that, carefully try to peel the layer. If that does not work, I recommend trying peeling while it is still slightly warm. Keep in mind, warm, not hot.

Temperature too low or too high

The temperature that you need to use for this process will depend on the type of HTV you have bought. Some will work on lower temperatures and others on higher. So, before you do anything, make sure you read through the instructions or the specifications of the heat transfer vinyl. Once you are certain at which temperature you should operate, it is time to start.

Whatever you do, make sure you stick to that temperature that is required. If you do not, the vinyl will not stick to the surface.

Not enough pressure

Whether you want to put a sticker on a window, a drinking glass, or a t-shirt, you will have to add enough pressure for the vinyl to stick. Otherwise, the adhesive cannot properly stick to the surface/material. The pressure applied is especially important for shirts and other similar fabrics. Since surfaces such as metal or glass are much smoother, the adhesive sticks easily. But, if you want to get the glue to properly stick to your shirts, you will have to increase the pressure.

If working on soft fabrics, too much pressure will not hurt the process. It could, but it rarely does. So, next time, try adding a little bit more pressure and see whether that fixes your problem.

Lower quality heat transfer vinyl

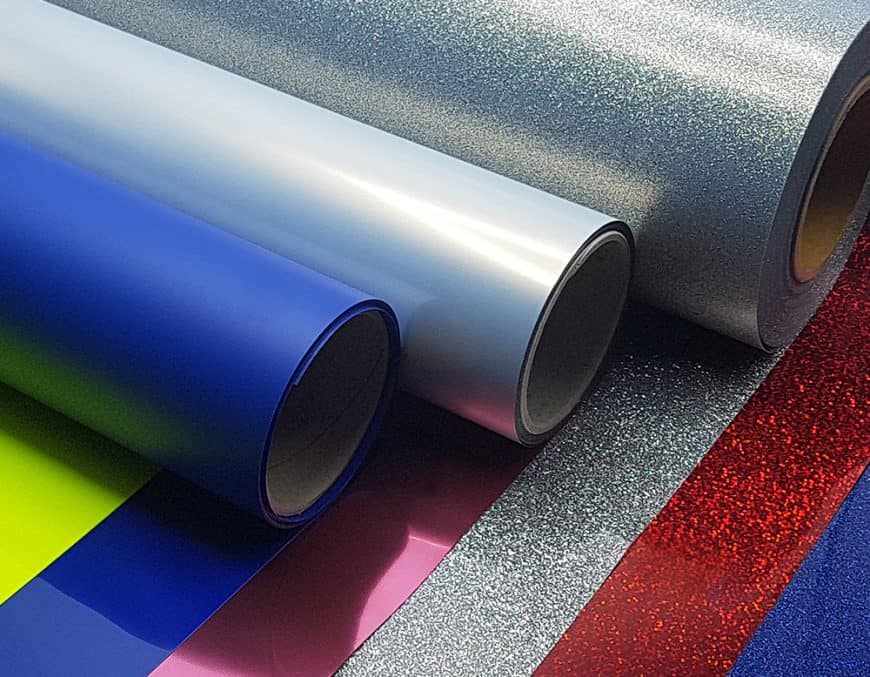

Not every heat transfer vinyl is equal. Many companies want to cut costs on these types of products, so they cheap out on the material. It is no wonder why so many of these HTVs are not sticking to the desired item.

The solution to this problem is simple. You will probably have to buy new high-quality HTV rolls. If you find those rolls to be too expensive for your needs, you should consider checking out heat transfer vinyl wholesale. Those usually sell high-quality goods for a much lower price.

The print falls off

Many people complain that their HTV print quickly starts to fall off after a few washes. But, the problem is not exactly with the vinyl. I think that the issue is with the user. Improper laundering of the clothing or washing of the item can cause the print to peel off. This is not really surprising. Heat, soap, and water can easily dissolve the adhesive holding the fiber and sticker together.

If you want your prints to last as long as possible, I recommend that you avoid washing machines. I know, washing by hand is not exactly fun or practical, but it really is the best way to protect the print. Cold water will not have any kind of impact on the adhesive. If your washing machine supports it, run the shirt through a cold water program.

Low-quality print

DIY projects are always fun, but no one said they were easy. It is normal to go through one project several times to get those good results you are looking for. This is why so many shirts end up with a low-quality print.

However, if you are sure that you are doing everything properly and you are still ending up with a low-resolution result, maybe there is something wrong with the vinyl or the design itself. Double-check those two things and see whether they are the cause of the issue.

Difficult to cut

Even though heat transfer vinyl seems quite thin and fragile when you hold it in your hands, it can be surprisingly difficult to cut it into the right shape. This happens because you probably have the wrong type of knife or a dull blade.

To fix that, I recommend getting a regular box cutter. But, if you can, try to find a flock blade. They are much more precise for cutting this type of material.

There are probably a few more issues that you will run into during your DIY projects, but those can easily be resolved. The ones I mentioned in this article are where you can get stuck. So, make sure to remember the solutions to these problems.