Streamlining Warehouse Operations: Tips for Optimizing Your Space and Workflow

In today’s fast-paced business environment, efficient warehouse operations can be the difference between success and failure. Effective warehouse management requires a streamlined workflow, optimized space utilization, and efficient logistics. In this article, we’ll explore some essential tips for streamlining warehouse operations to optimize your space and workflow.

Organize Your Warehouse Layout

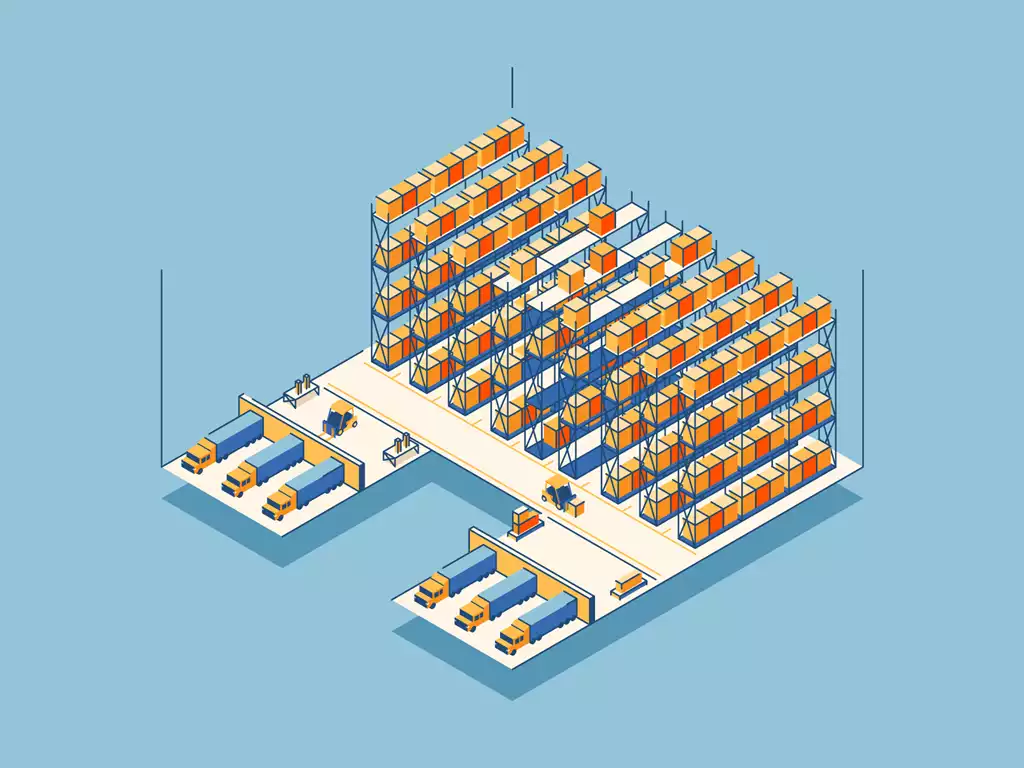

Organizing your warehouse layout is crucial to streamlining your warehouse operations. Design your warehouse with a flow that maximizes efficiency, improves safety, and reduces errors. Ensure that your warehouse layout has designated spaces for receiving, storage, packing, and shipping.

Use Automated Systems

Incorporating automated systems into your warehouse operations can help save time and improve accuracy. Incorporating automated systems into your cold storage warehouse operations can be especially beneficial due to the unique challenges presented by the need to maintain specific temperature and humidity conditions. You can use automated systems like conveyor belts, palletizers, and automated storage and retrieval systems (AS/RS) to streamline your warehouse operations. These systems can handle repetitive tasks, reduce labor costs, and increase throughput.

Implement Lean Principles

Implementing lean principles is an effective way to optimize your warehouse workflow. Lean principles emphasize the elimination of waste, the use of standardized processes, and continuous improvement. Applying these principles can help you reduce lead times, minimize inventory, and increase productivity.

Optimize Your Inventory Management

Optimizing your inventory management can help you reduce costs, improve order accuracy, and increase customer satisfaction. Use a warehouse management system (WMS) to track inventory levels, manage order fulfillment, and reduce stockouts. The WMS can also help you optimize order-picking routes, reduce cycle times, and increase accuracy.

Invest in Equipment Maintenance

Maintaining your warehouse equipment is crucial to ensure that it performs optimally. Schedule regular maintenance for your equipment, including forklifts, conveyor systems, and pallet jacks. Proper maintenance can help you avoid costly breakdowns, extend equipment lifespan, and improve safety.

Use Effective Space Utilization Strategies

Effective space utilization strategies can help you maximize your warehouse space and optimize your workflow. Use vertical storage systems to increase storage capacity, and make use of overhead space. Implement slotting strategies to ensure that fast-moving items are placed closer to the packing and shipping areas.

Train Your Staff

Your warehouse staff plays a critical role in streamlining your operations. Invest in training to ensure that they understand the importance of safety, efficiency, and accuracy. Train them on the use of equipment, inventory management, and lean principles. Encourage them to provide feedback on ways to improve warehouse operations continually.

Monitor and Analyze Performance

To ensure that your warehouse operations remain streamlined and efficient, it’s crucial to monitor and analyze performance. Use key performance indicators (KPIs) to track metrics such as order processing times, inventory accuracy, and equipment downtime. Regularly analyze this data to identify areas for improvement and implement changes accordingly.

Conclusion

In conclusion, streamlining warehouse operations is essential for any business that wants to remain competitive. By implementing these tips, you can optimize your space and workflow, reduce costs, improve safety, and increase productivity. Organize your warehouse layout, use automated systems, implement lean principles, optimize your inventory management, invest in equipment maintenance, use effective space utilization strategies, and train and monitor and analyze performance.