5 Advanced Technologies in Laser Marking Market – 2024 Guide

Laser marking is one of the most revolutionary inventions in the modern industry. From a 2024 standpoint, it’s nothing new, but it is heavily used even nowadays as a technique that’s not getting “old” even the slightest bit. For those of you curious about this method of marking, we’ll make sure to explain everything about it in today’s article.

This technology came out somewhere in the 1970’s, but it wasn’t nearly as sophisticated as it is today. The person who came out with the idea was named Tom Rudy Zarden and changed the entire industry forever.

The way this works is by using a laser to cut, or should we say “scratch” the surface of a sturdy material, such as wood, metal, steel or anything else really, even plastic, in order to “mark” that material permanently. It’s different than other marking types because this method is permanent. When you mark something with a paint for example, you can always remove that paint, or if it’s a stronger one, scratch it somehow out of the material. With engraving, the laser basically removes parts from the surface of the material in a computer-generated pattern that you configure before the procedure is started.

Now, just like any industry, this one continues to advance constantly. That means we constantly see new technologies and trends in it, right? True, let’s take a look.

1. CO2 Lasers for non-metallic materials

As you’ve probably guessed, there are many different types of lasers people created in order to “personalize” and speed up their marking process. The entire industry goes forward because of these multiple variants when it comes to the machines and their types. If your business works with non-metallic materials for example, purchasing CO2 lasers is the most efficient solution for increased productivity.

CO2 lasers re used very efficiently for glass, acrylic, leather, stone, wood, plastic and a lot more. Plexiglass as well. They are widely implemented in the food industry and they are used for advertising signs as well. In short, CO2 lasers are used for natural materials.

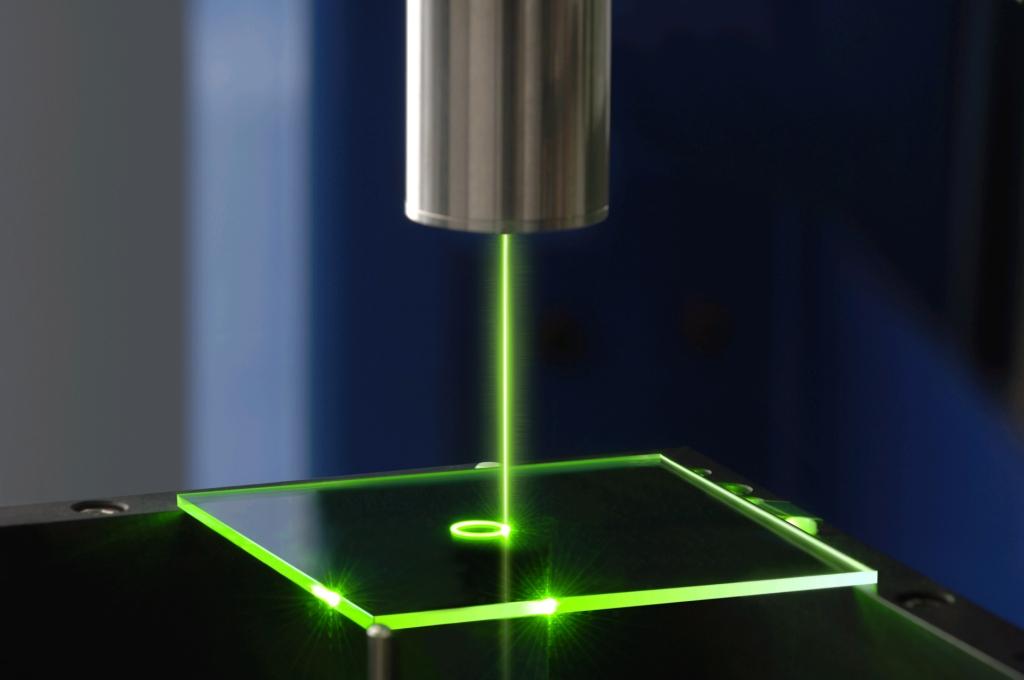

2. UV Lasers for engraving glass and textile

Sometimes consumers require products that are slightly more difficult to make. For example, décor made out of glass is pretty fragile, we all know that. And, we also know that you cannot really modify glass by using hardware. In case you want to engrave it, you have to use something that’s very precise and doesn’t use raw force in order to make the chances. This is where UV Lasers come into play.

A few common examples where UV lasers are used are decorated glass plates, ceramic mugs, computer parts such as motherboards, phone chargers, bottles and a lot more. It’s difficult to picture all this and the way it works if you are not even remotely familiar with laser technologies, which is why we suggest that you do some research on the internet on reputable websites that explain things in detail. If you can’t find any, or you don’t want to spend a lot of time researching, hispeedlaser.com is an example that can serve you well.

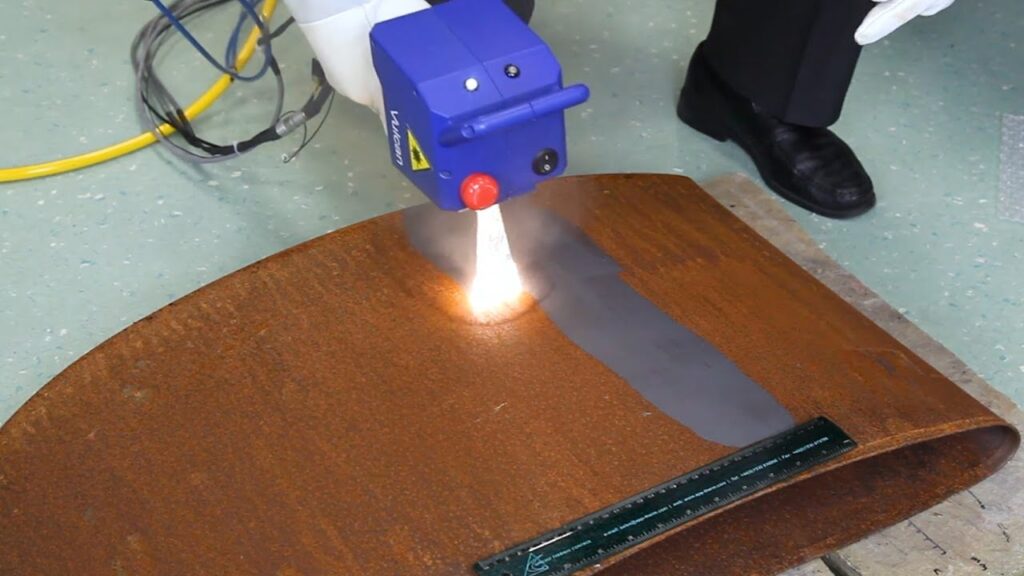

3. Laser Cleaning and Detailing

Some people would think that lasers are “destructive”. Not in a way that they don’t help us move forward in the industry, but in a way that they can only remove parts of a material in order to reshape it. That’s true, but the way they remove things makes them productive, instead of destructive. This probably doesn’t make sense when you first hear it, but let us explain how laser cleaning works.

So you have a piece of a material that’s very valuable to you, but in the past few years it hasn’t been stored properly. Due to the unwanted storage circumstances, the material managed to accumulate various unwanted materials on it. Let’s say we’re talking about a gun frame. You have this really old rifle that was a family legacy, and now you want to make the frame or the barrel shiny again. Or, perhaps you want to engrave the name of your grandfather on it as a gift. Well, all of that is possible with a laser.

Firstly, cleaning works by gently removing the “polluted” or “impure” parts of the material. A laser used for cleaning can remove carbon, silicon, rubber, glue or anything else that may be on your material. Then, on the freshly cleaned surface, you can engrave the name you want on it by using a marking laser. As we said above, CO2 lasers are best for natural surfaces.

4. Advanced Laser Welding of Materials

Welding no longer has to be done using outdated tools and the regular old-school welders most of us have in our garage. Nowadays, people weld using lasers. It may sound a bit futuristic, but it’s the truth, and, results are better than ever. The reason why this technique is rising in popularity so much is due to the longer-lasting weld results. The weld is stronger and it’s done a lot more precisely. Very useful if you are doing some delicate work on a smaller object for example. Medical equipment and aircraft parts require immense precision, so the welding part has to be “pixel perfect”.

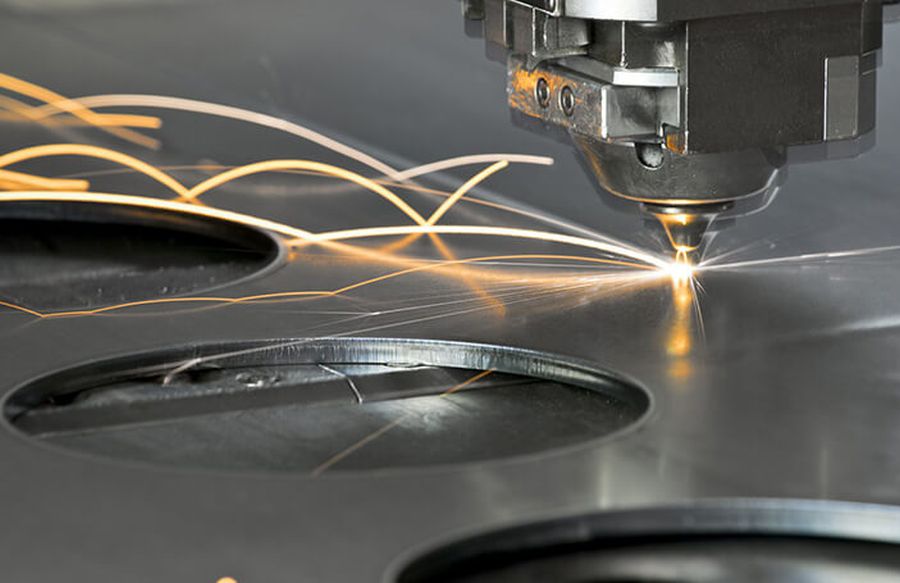

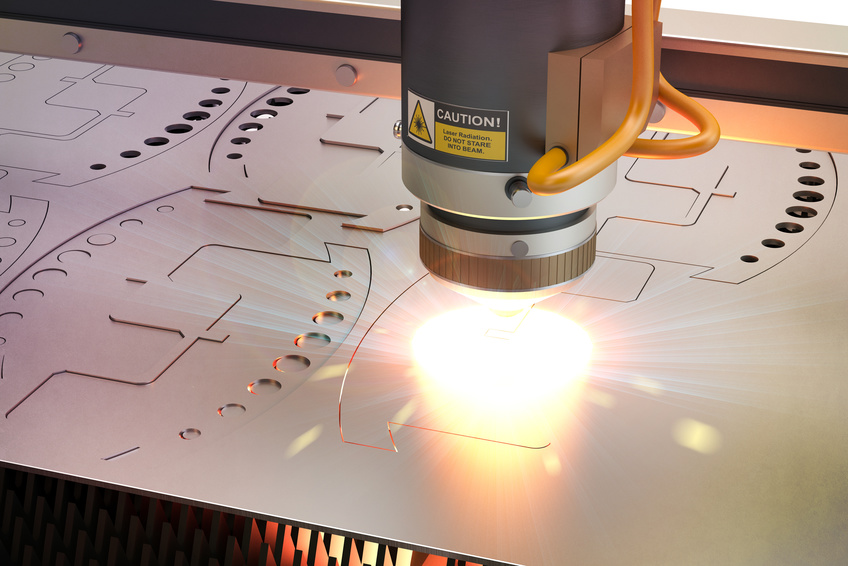

5. Laser Cutting

Last but not least, the main reason why lasers were invented in the past was for cutting materials a lot more precisely than it is possible with any other type of a tool. So, it’s worth mentioning that this particular field in the industry will only go forward in the future, and costs will decrease while more complex tasks will become easier. You can pretty much cut everything with a laser nowadays, but the patterns can become a lot more precise and complex as the software improves in the future.

Conclusion

Without lasers, our world would be a very different place than it is right know, so it’s pretty much safe to say that these machines and the industry itself plays a huge role in the human race progression. Cameras, smartphones, computers, medical equipment and a lot more depends on the use of lasers.