6 Ways Technology has Improved the Manufacturing Industry in 2024

Manufacturing is a crucial segment of every economy. While the service industry has grown in importance over the last few decades, there’s no denying that an economy simply can not succeed without the growth of its manufacturing industry. Today, the global market for manufacturing and process control is valued at $86.7 billion and is expected to grow at 6.3% until 2025, valuing at $117.7 billion.

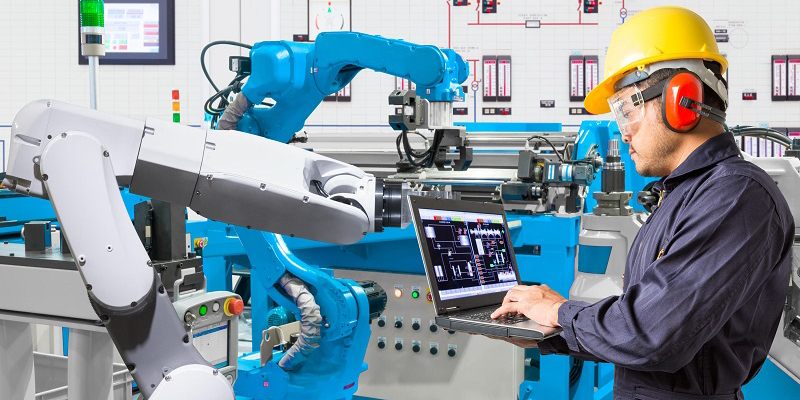

One factor that contributes to this significant growth is technology. From advanced robotics to data analytics, technological developments have been a game-changer for the industry, reducing human involvement, improving efficiencies, and boosting overall productivity.

In fact, these modern technologies are rapidly changing the future of manufacturing by transforming many areas. Productivity is a critical factor in any manufacturing firm, and every business must invest in these technologies to continue to retain its competitive advantage.

For more info on how technology contributes to a manufacturing firm, it’s important to understand how it can help manage complex operations. Given how important it is, here are six ways you can use technology to improve your manufacturing processes:

1. Improved Efficiency

Technology ensures your production time is used in the best way possible by reducing processing time and automating tasks that would otherwise take too much time when performed manually. Technological developments help reduce lead times, decrease waste, and increase flexibility in the production process.

Even working on minor areas, such as automating emails and incorporating an HR system, can help save valuable time, allowing your staff to focus on other areas that demand more of their attention. To determine which areas could benefit from technological development, you should conduct an overall business audit that helps evaluate improvement areas.

2. Increased Productivity

The key to success for a manufacturing firm is its productivity. Higher productivity can help you manufacture more products in less time. It’s vital to be on the lookout for technological solutions that can boost it.

For instance, inventory management solutions can help you track and monitor workflow. Additionally, incorporating automation can help reduce the risk of error, thereby boosting productivity since there are fewer setbacks to manage. When used correctly, technology can enhance your bottom line.

3. Data Management

Every manufacturing business has access to volumes of data requiring management. This data can become overwhelming to handle if you’re not experienced enough to handle it. In fact, data management can contribute to overall profitability by helping you improve your manufacturing processes. It would help if you looked into cloud management, which helps accumulate your data in one place and keeps it secure.

Of course, data analysis is as critical as management. There’s no point in having volumes of data if you don’t know how to understand it. You need to understand what this data means to ensure you can use it effectively.

At the same time, it’s vital to protect the data since it involves critical information about your customers, clients, and operations. Ensure you’re encrypting it and backing it up in case of a cyberattack. Additionally, your employees also need to be informed about how they protect this information.

4. Better Quality

Manufacturing firms may sometimes be affected by product recalls, which often occurs in the food industry where 337 recalls were issued in the United States in 2019 alone. Implementing technologies can help you identify areas of improvement through manufacturing intelligence that highlights supply chain issues and identify which manufacturing process produced the most defective results.

For instance, if a customer returns a product during the warranty period due to a defective part, technological software can pinpoint where the product was returned due to material or supplier issues. In this case, an organization can make changes to improve quality and prevent similar problems in the future.

5. Enhanced Communication and Collaboration

For any business, technology can help improve business communication encouraging collaboration between employees. This is especially important for manufacturing firms since there’s coordination between warehouses, retail and, of course, the plant.

With technological tools such as video conferencing apps like Skype, you can ensure your employees won’t be facing any communication barriers that may impact overall efficiency. Additionally, it also helps collaboration through file-sharing tools, for instance, and allows your workers to schedule meetings and deadlines on the calendar.

6. Greater Visibility

The success of every manufacturing firm depends on how perfectly it makes its products. While this was previously difficult to achieve, technology has made it possible for firms to produce near-perfect ones. By implementing AI in your production process and incorporating the internet of things (IoT), your machines can communicate with each other and react accordingly in case of issues.

This way, a machine alerts employees and other machines to ensure the problem is addressed in real-time. Apart from this, your machines can now detect defects the regular eye won’t spot. Thus, increased precision results in lower product failures and error rates, thereby reducing overall costs significantly.

Final Thoughts

As the advancement of technology introduces new developments, manufacturing will continue to improve as it adapts. The industry has a lot to gain from technologies such as AI and IoT, which will scale it to new heights. As manufacturers continue to embrace these developments, the industry will likely witness increased profitability and productivity.

It will undoubtedly be interesting to see what modern technologies will be introduced and which facets of the manufacturing industry will be affected in the future. However, one thing’s for sure, any firm intending to remain relevant in today’s highly competitive world must stay updated with technological developments to stay on top of their game.