What is the Primary Function of a Linear Bushing?

If you take a look at today’s methods of creating a wide array of different constructions, you will see that a vast majority of processes have been automated completely. For those who are not familiar with the term “automatization”, it means that these processes are doing a majority of work on their own. So, there is no need for a human to control it. Surely, overseeing this process adds a whole new quality.

But, generally speaking, there is no need for frequent interferences. As you probably know, there are a plethora of processes that can be conducted this way. But construction machines and furniture are probably the commonest ones. It is done by conducting this process by using some high-precision motion applications. With these, the possibilities are countless.

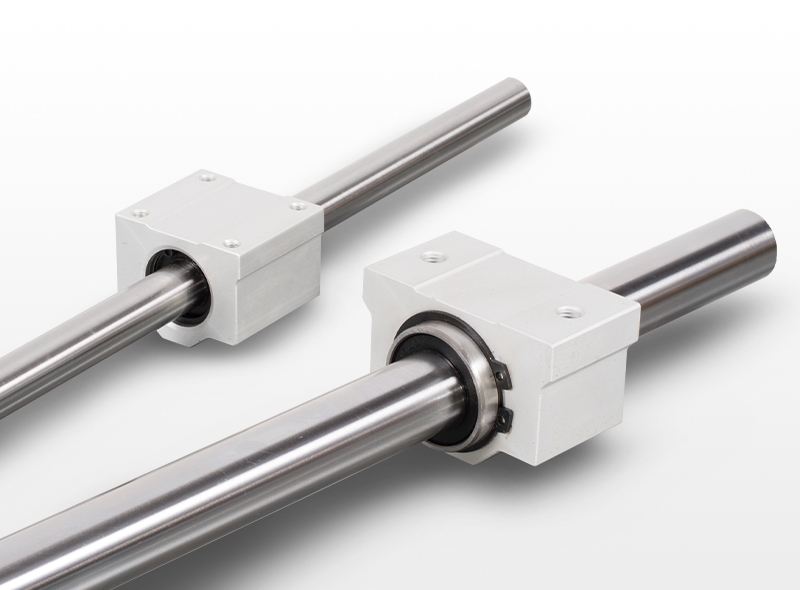

One of the technologies used by these motion applications is the linear bushing. Without any doubt, these are one of the most precise items available for these processes. If you want to take a look at how the items needed for this process look, visit tuli-shop.com. Today, we would like to talk about linear bushing in greater detail, and explain what is the primary function of this approach.

Let’s take a look at the most important points.

What are the Main Characteristics?

In most cases, you will see that ball-bearing motion elements have an average load capacity. However, when two devices are attached on the opposite sides of the machine, they can support a load that is not so easy to bear in a vast majority of cases. Since these two sizes are getting closer to each other, until the part attached to both of these sides is not perfectly connected, there is friction involved.

If the pressure is not as high as it needs to be in a vast majority of cases, the friction will be much lower in intensity. If you didn’t notice, we are talking about linear bushing. We are talking about a situation when the two equal parts will be a crucial factor in having a chance to create enough holes in the material, so it can be used in attaching while creating some sort of machinery or a piece of furniture.

Little is known that this technique can be used by CNC machines. Just think about it, making a certain object, that needs to be of a particular shape, becomes much easier with this sort of approach, and of course, using proper equipment. Sometimes, these two parts will require additional lubrication to achieve much better performance for a particular project. All of these factors are crucial for conducting a proper use of linear bushing.

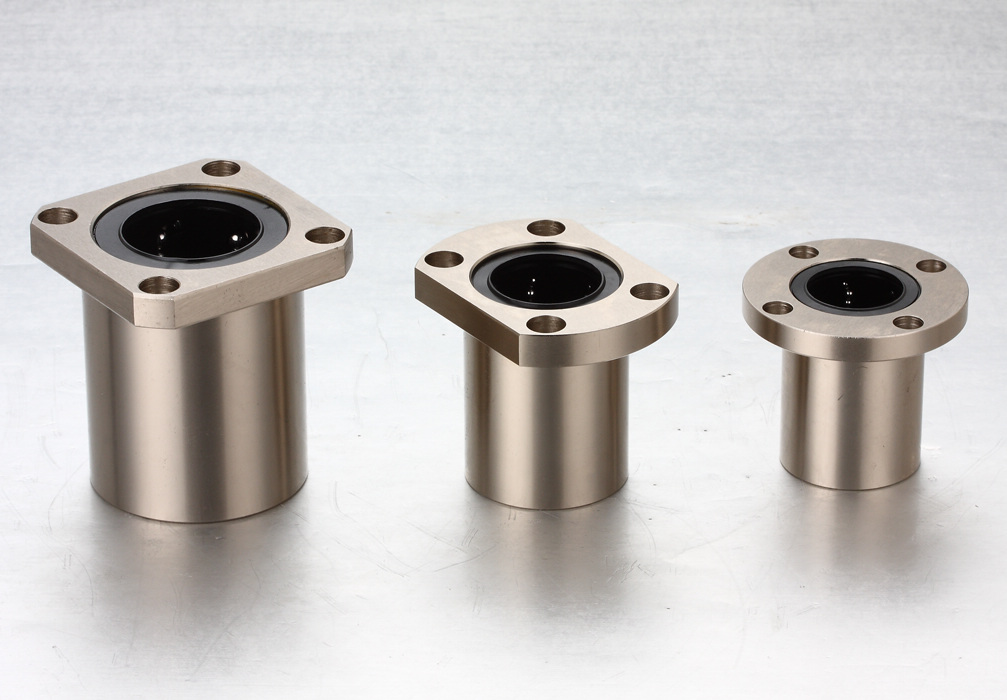

At the same time, it is quite obvious that you need to be careful about the materials used for creating bushings. For instance, you will see that bronze is a material that can provide you with a lot of flexibility. The reason is quite simple, this material will have a positive effect on practically every material you are about to work with. But that doesn’t mean that this is the only option you can select. There are many of them.

Bushing vs. Bearing

We can see that many people are confused about what are the differences between bushing and bearing. It is quite obvious that these two terms are pretty similar. However, there is a vast difference between the ways you can use them, and the conditions needed for them to act efficiently. But when we are talking about the actual process, there are not too many variances between these two processes.

The main way these two differ is that bearing uses two surfaces, and makes them roll over each other. When this is done, the friction will be much less than is the case with bushing. Once again, we feel it is important to talk about the importance of material and shape involved in the process itself. Surely, you cannot expect a successful process if these two surfaces are not compatible with each other, right?

The easiest way to explain these two is to say that bushing is practically a bearing. However, you can see that bearing is not always busing. Meaning, the bushing will provide you with much more options. Still, it needs to be said that you should use it only when you have the actual need for it. Otherwise, the efficiency will not be as high as you want it to be. So, be sure to check what you need before the work starts.

How Big is the Industry?

If you ask around what people know about the linear bushing, you will see that even some of the experts perceive it only as a part of the bigger process. However, the truth is that this approach is big enough to create an industry that generates serious income every year. According to some market reports, you will see that this industry generates more than $700 million every year, on a global scale.

Even though it generates a lot of money, it is not perfect. In fact, there are a couple of downsides that prevent it from becoming even bigger in the future. For instance, the biggest restraint is the high cost of installation for low-volume production. Surely, you will agree that it would be used much more if some smaller projects would have a chance to implement it successfully, without spending a lot of money.

When it comes to the biggest drive-forces behind the market, you can see that there are two of them. First is the increasing need for quality inspection and automation. The second one is the growing demand in the semiconductor industry. These two elements make the biggest chunk of positive sides of this industry. Even though there is a serious setback present at it, we are confident that it will be overlooked with the adoption of advanced technologies in the future.

Summary

Since there is a lot of confusion and misconceptions about linear bushing, it is not uncommon to see people fail to understand the primary function of this approach. Here, you can learn about all the relevant information for this approach. We are sure you will have a much clearer idea.